![]()

Pangborn UK have yet again have been busy at the forefront of fresh installations, most recently for a customer located in Ireland.

Many of our customers are located throughout the world, in almost every country. Pangborn UK are a main port of call for customers based within the UK and Ireland.

Recently, our team of expert engineers and rapid response installation teams have crossed the water to supply one of our Irish customers with a well-needed and much more efficient installation of a new machine.

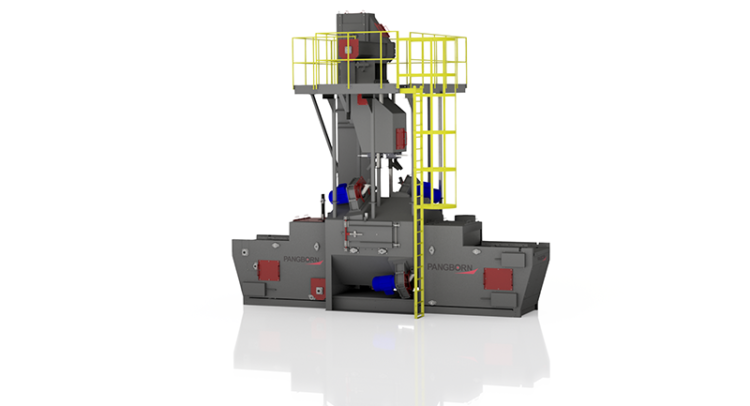

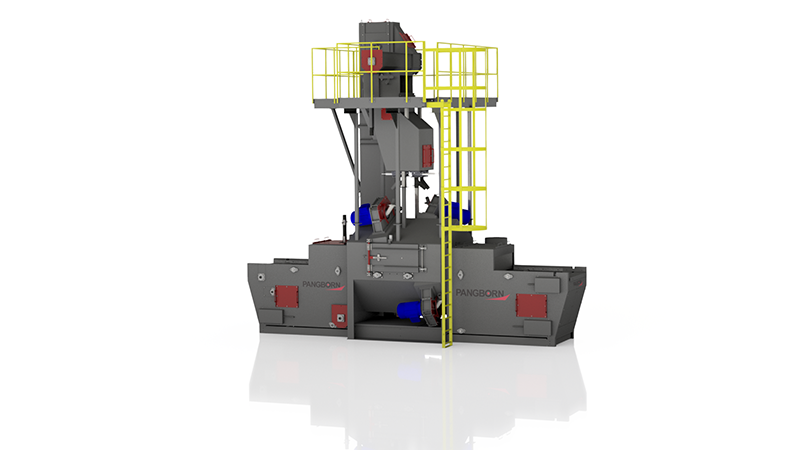

New Installation – Wire Mesh Belt Blast Machine

The Wire Mesh Belt Blast Machine is one of our most popular types of commercial blast cleaning systems.

Designed with the ability to blast heavy duty small to medium sized work pieces as well as fragile castings. The blast chamber is bombarded with abrasive stemming from wheels situated above and below the work for maximum coverage.

This type of blasting machine is specifically designed to blast clean pieces on two sides, with only one pass through. The Wire Mesh Belt Blast Cleaning Machine is aggressive enough to handle heavy duty foundry applications, as well as gentle enough to cater for thin and fragile castings.

Features and Benefits

P-41 Alloy and Steel Construction for:

- Enhanced durability

- Machine longevity

Acu-Strike Wheel Technology:

- Better abrasive control and improved flow boosts machine performance and productivity

- Enhanced durability and longevity

- Ease of maintenance

- High/Low/Variable speed options for flexibility and precision

High Efficiency Separator:

- Consistent blast quality and abrasive flow for a better finished product and more efficient operations

- Optimized contaminant removal

- Paint savings

- Better abrasive life for cost savings

Electronics Package:

- Multiple package options to meet your needs (Basic, PLC/Touch Screen, PC based)

- Remote connectivity for easier and more efficient troubleshooting and maintenance

- Back office integration and data collections for improved operations

Machine Specific Features

- Integration of blasting process into automatic production lines reduces production costs

- Wear plate package consisting of 1/2″ (13 mm) thick cast wear resist or manganese liners bolted in line with blast streams

- Systems designed for floor line installation requiring no pit

More Details

For more details on the Pangborn Wire Mesh Blast Cleaning Machine or to arrange a consultation. Contact Pangborn UK on – 01352 712412, or email us at – info@pangborn.co.uk.