![]()

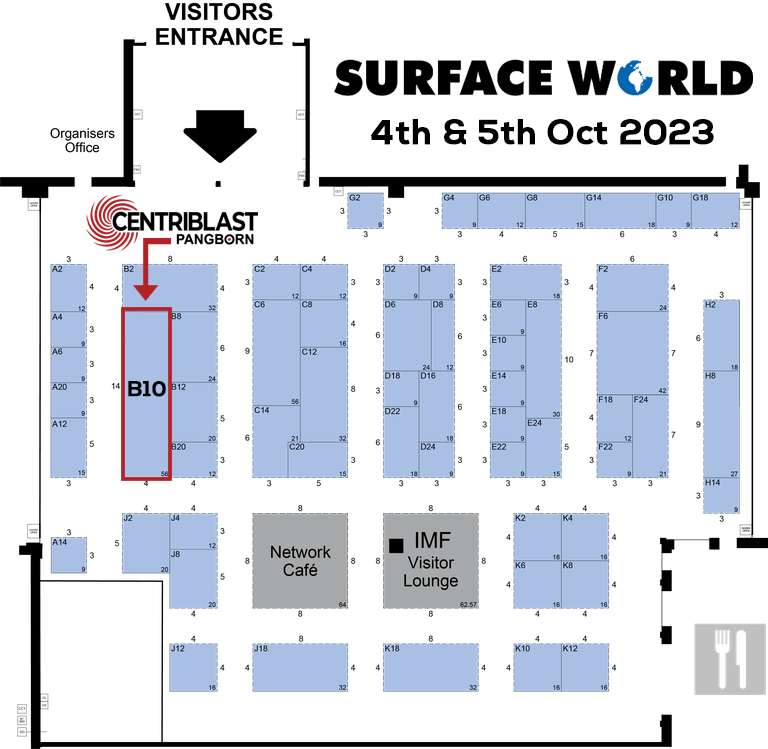

Join is at this years Surface World 4th and 5th of October – Birmingham NEC: Only 2 Days to Go!

Transform your surface preparation game with the cutting-edge Centriblast 4D1100 Vertical Blast Cleaning Machine! Are you tired of putting in endless time and energy for surface preparation? If so, are you searching for a solution that can effectively clean, descale, and purify a variety of materials? Your search ends here!

We will be showcasing the Centriblast – Pangborn 4D1100 Shot Blast Machine, the game-changing solution for your surface preparation needs. Harnessing cutting-edge technology and unbeatable performance, this machine will quickly become your go-to for achieving flawless results.

Prepare to discover a game-changing option that stands out in the industry and will elevate your productivity and profitability! 🚀🚀🚀

Advantages of the 4D1100 Roller Conveyor Blast Machine…

Centriblast-Pangborn 4D1100 Roller Conveyor Blast Machine is Industry Leading, Patented Technology.

Roller conveyor blast machines are capable of handling a large volume of workpieces, allowing for high production rates. The continuous movement of the workpieces ensures a consistent and uninterrupted blasting process, reducing downtime and increasing overall efficiency.

![]() Uniform Surface Treatment

Uniform Surface Treatment

- The roller conveyor system guarantees that each workpiece is exposed to the abrasive media at the same angle and intensity, ensuring uniform surface treatment. This results in consistent quality across all the processed pieces, minimizing variations and defects.

![]() Versatility

Versatility

- Roller conveyor blast machines are highly versatile and can accommodate a wide range of workpiece sizes, shapes, and weights. The adjustable speed and configuration of the conveyor system allow for customized blasting operations, catering to the specific requirements of various industries.

![]() Automation and Integration

Automation and Integration

- These machines can be integrated into existing production lines, facilitating seamless automation and workflow. With the option of incorporating loading and unloading mechanisms, roller conveyor blast machines offer improved process control, reduced manual labour, and increased safety for operators.

![]() Cost-effective Operation

Cost-effective Operation

- Roller conveyor blast machines optimize abrasive media usage, reducing waste and operational costs. Additionally, their high throughput capacity ensures faster processing times, translating into shorter production cycles and enhanced cost-efficiency.

Technical Details

The Centriblast-Pangborn 4D 1100/686 V Roller Conveyor Shot Blast System has a processing range of 1100mm wide x 686mm high. The machine is designed to clean the following range of components;

| Maximum plate width | 1000mm |

| Maximum plate thickness | 60mm |

| Minimum plate thickness | 4mm |

| Maximum section size | 686mm x 254mm U.B. |

| Maximum hollow section | 350mm x 350mm |

| Maximum pipe diameter | 600mm |

This type of Conveyor Shotblast System is Powered by 4x 11kw Acu-Strike® blast wheels, throughout speeds of 0.5m p/min – 3.5m p/min. This system can be operated as part of an automated, in-line system or as a standalone system.