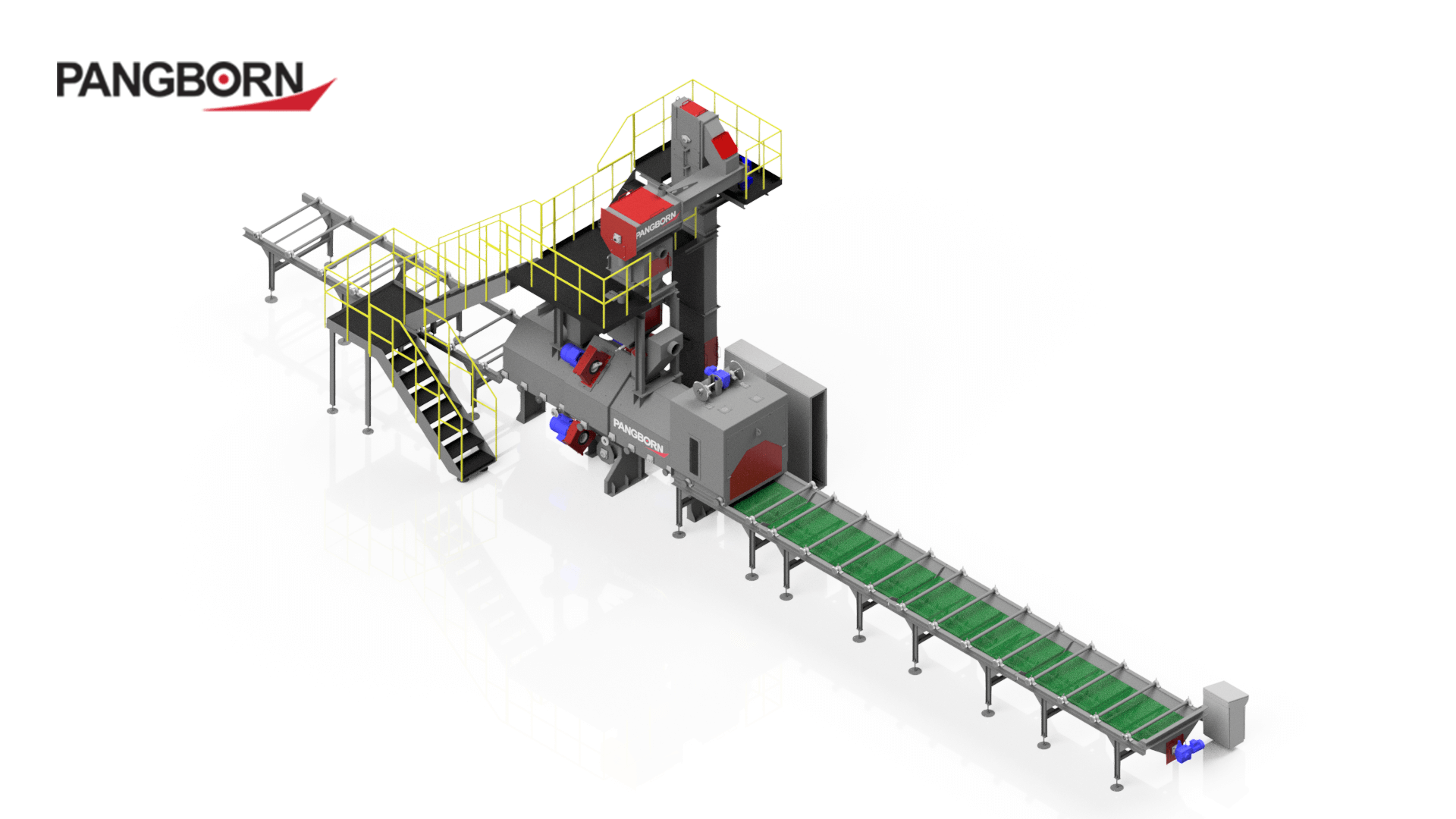

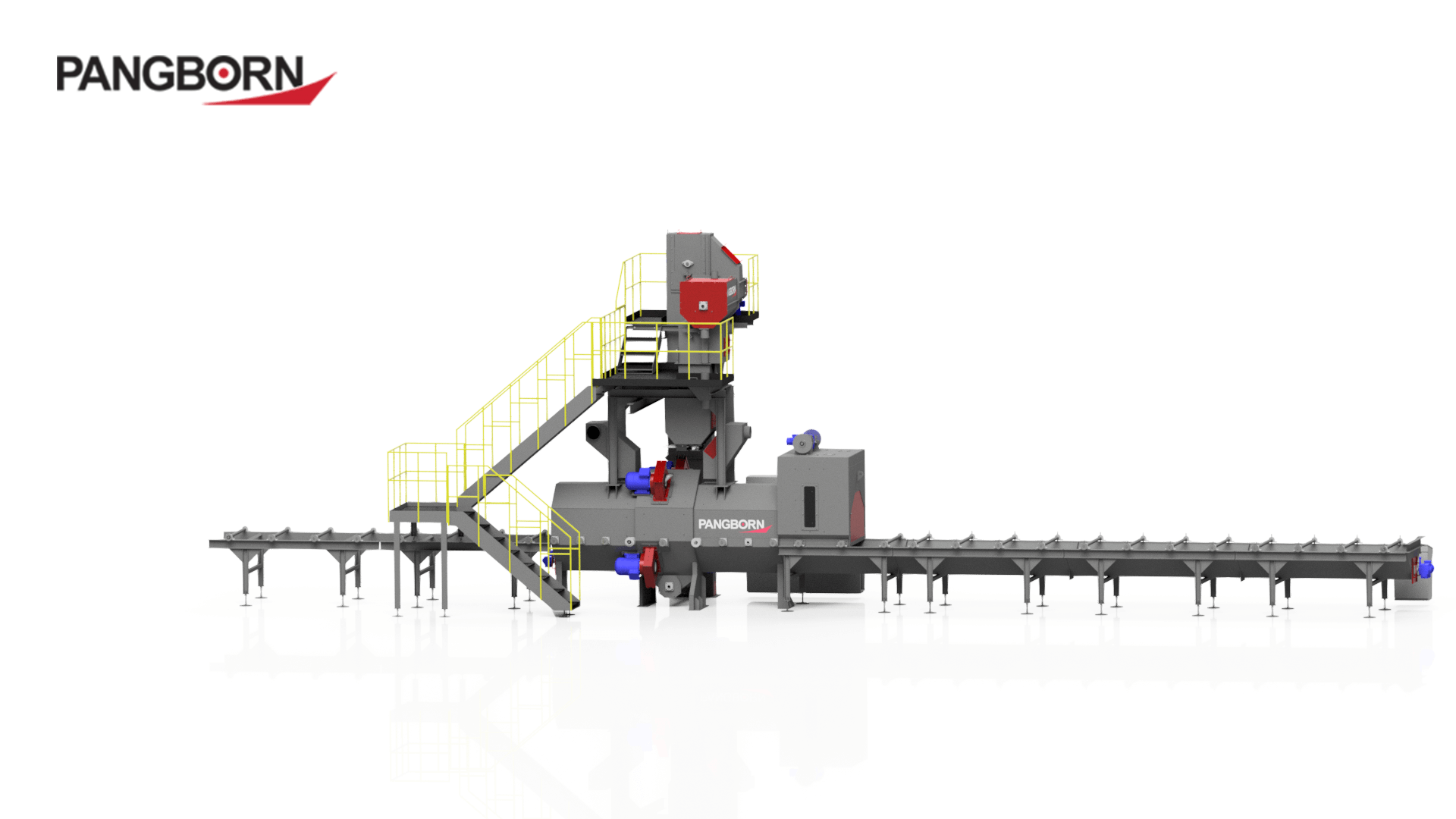

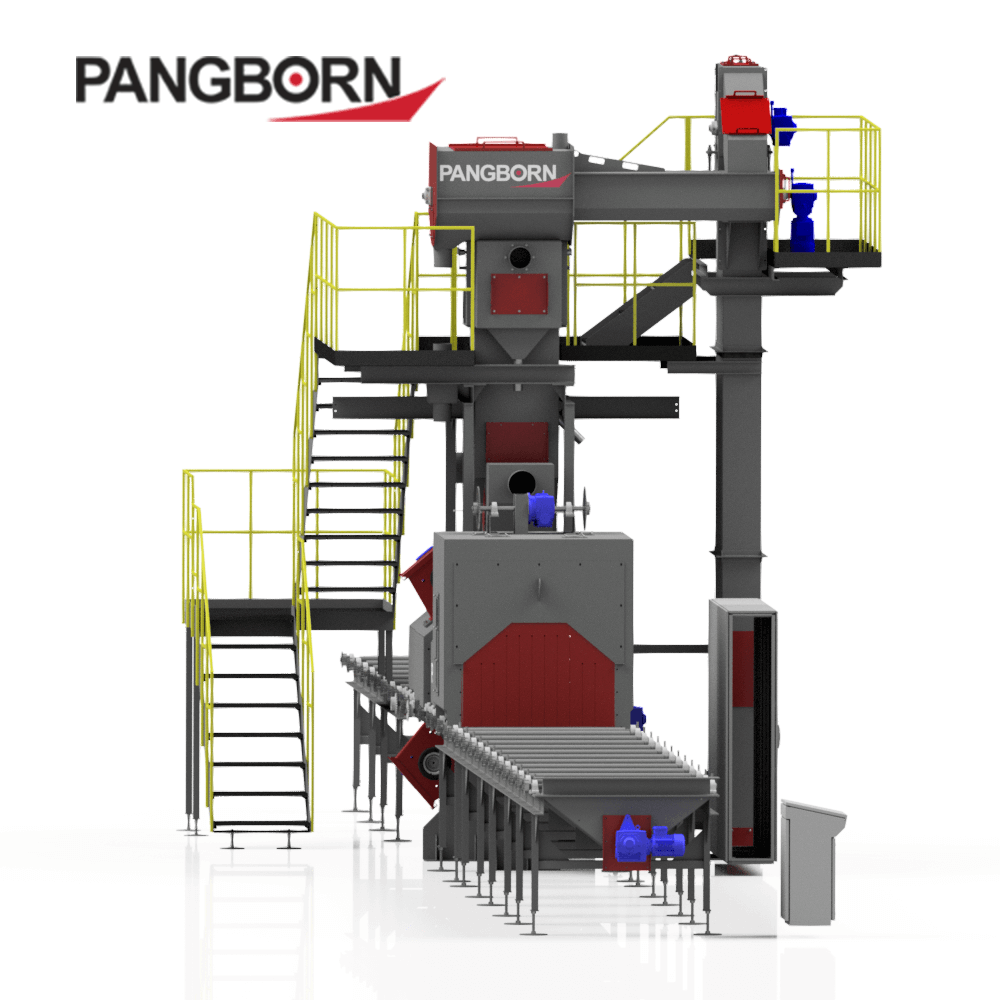

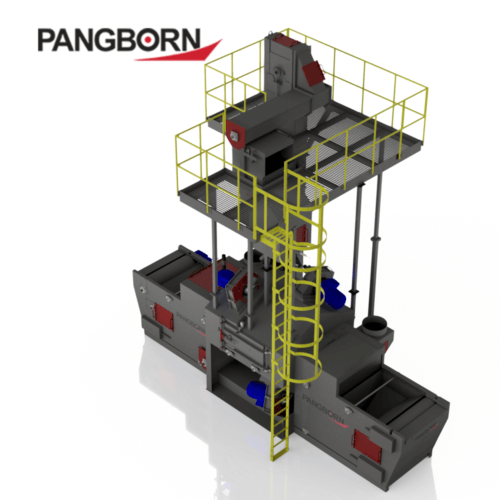

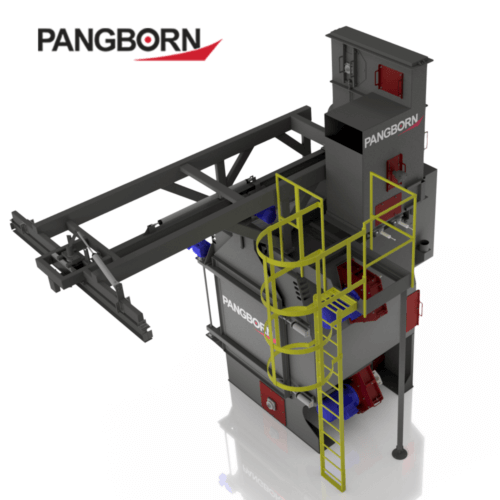

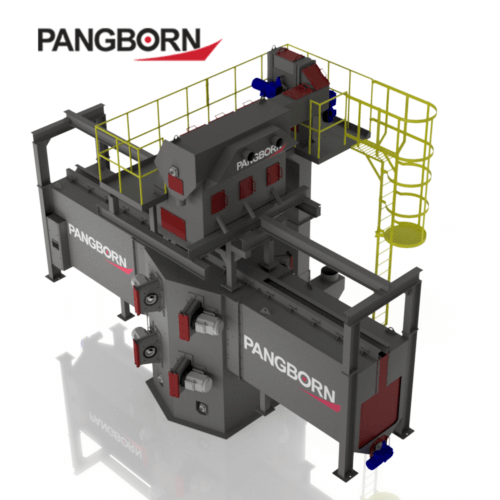

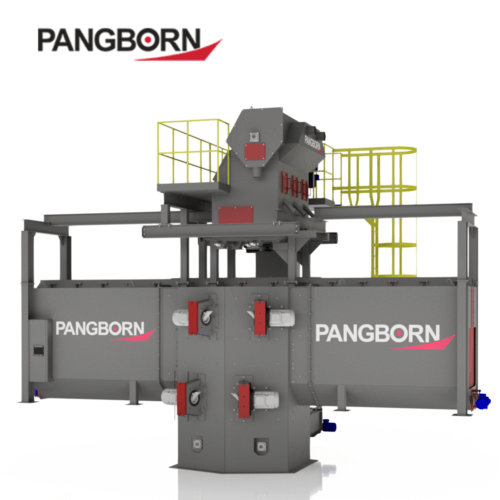

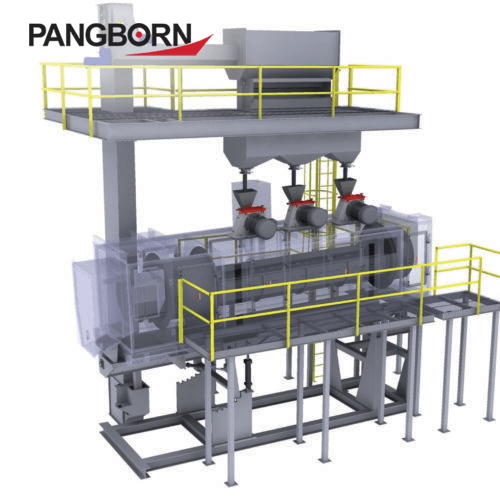

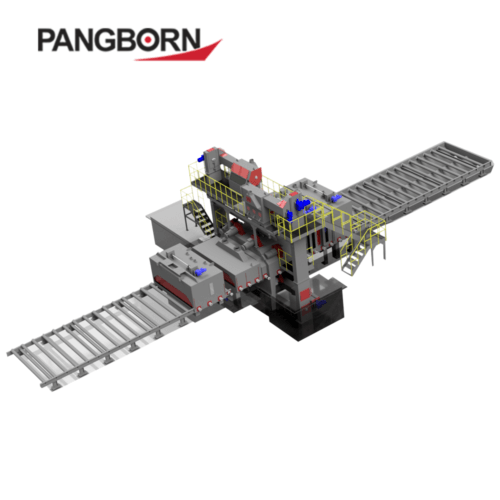

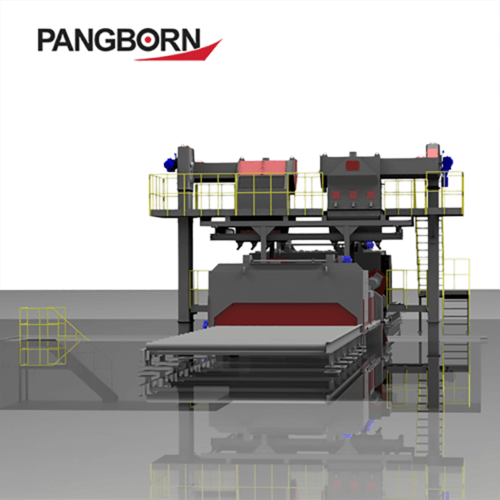

Pangborn UK offers a wide range of low energy, standard blast cleaning systems with 4 or 6 wheel units for vertical section, profile, pipe and occasional plate cleaning. Suitable for small structural steel or fabrication companies or contract blasters with output of up to 80 tonnes of steel per week.

Pangborn UK offers a wide range of low energy, standard blast cleaning systems with 4 or 6 wheel units for vertical section, profile, pipe and occasional plate cleaning. Suitable for small structural steel or fabrication companies or contract blasters with output of up to 80 tonnes of steel per week.

Available on back-order

| NOTE: | Designs differ in the number and placement of blast wheels and air nozzles, and incorporate a variety of material handling systems. |

|---|

Specifications

Blast Wheel Speed

Variable from 2200 to 3800 RPM when fitted with optional electronic inverter control.

Blast Wheel Type

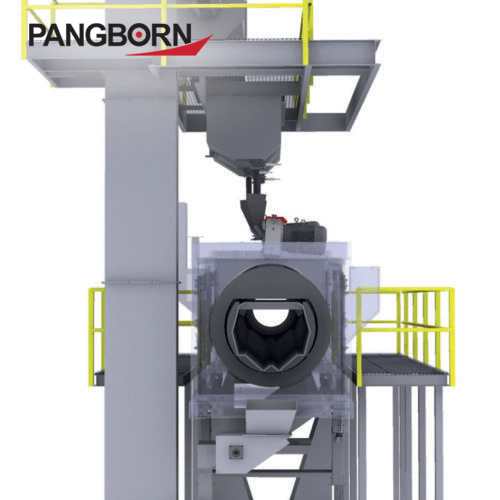

Pangborn RIM-LOC 8 Vane type reversible rotoblast wheels, achieve faster cleaning and feature the easiest and quickest maintenance vane change in the industry.

Machine Operating Speed

When fitted with 7.5 kW or 11.0 kW wheel motors the average throughput speed is 1.25 m – 1.5 m per minute when cleaning to SA2.5.

Abrasive Control System

Single or individual quadrant valve activated by sensor or manual push button.

Blast Cabinet Protection

Cross rolled manganese steel.

Blast Cabinet Floor

High chrome alloy steel perforated floor plates.

Abrasive Recovery System

Heavy duty screw conveyors, belt and bucket elevator and cascade type airwash unit.

Phil Pilling –

St Helens Plant have had the Pangborn Vertical Blast Cleaning Machine installed now for over a year, replacing our previous Pangborn shot blast machine that lasted us over 20 years.

We’ve already seen massive improvements in productivity and output we can produce. Fantastic company, quality and support is second to none. Outstanding customer service every step of the way thanks to Nick Evans and Steve Cooper, the whole process was seamless from order to installation.

St Helens Plant we would not use any other manufacturer for the vital machinery our plant needs.

Phil Pilling, Director – St Helens Plant Limited