![]()

Shot blasting is a highly effective method that not only cleans the surface but also provides several advantages.

Let’s take a closer look at what shot blasting is and explore its many benefits. So, buckle up and get ready to blast away those surface issues!

Shot blasting has a number of advantages over other industrial processes, including:

- Relatively quick process, taking only a few minutes to blast a large area.

- Shot blasting is a non-invasive process, meaning that it does not damage the surrounding environment.

- Shot blasting can be used to remove a wide variety of materials, including metal, plastic, and concrete.

- Shot blasting can be used to remove a variety of materials, including hard and soft surfaces.

What is Shot Blasting?

Shot blasting is a method of preparing surfaces for painting or other finishes. It involves using a high-pressure stream of air or water to remove dirt, paint, rust, and other debris from the surface. This can be done by hand, using a pressure washer, or with special equipment designed for shot blasting.

Shot blasting has several advantages over other methods of cleaning surfaces. It is fast and efficient, and it leaves the surface clean and ready for painting or other finishes. It also does not require the use of harsh chemicals, so it is safer for the environment and for workers.

The Different types of Shot Blasting

There are four main types of shot blasting: wheel blading, Airblasting, centrifugal blasting, and wet blasting.

Wheel Blasting: Wheel blasting is the most common type of shot blasting. It involves a spinning wheel that hurls abrasive media at the surface of the workpiece. The media can be made of steel, ceramic, or other materials.

Airblasting: Airblasting uses compressed air to generate a stream of abrasive particles. This method is often used to remove rust from metal surfaces.

Centrifugal Blasting: Centrifugal blasting uses a rotating disk to hurl abrasive media at the surface of the workpiece. This method is often used to clean large surfaces quickly.

Wet Blasting: Wet blasting uses a stream of water to wet the abrasive media before it hits the surface of the workpiece. This method is often used to avoid creating dust during the blast process.

Types of Shot Blasting Equipment

There are several types of shot blasting equipment that can be used for different applications. The most common type is the wheel blast machine, which uses a rotating wheel to hurl abrasive media at the surface of the workpiece.

➡️ This type of machine is typically used for larger pieces of metal or concrete.

Another type of shot blasting machine is the air blast machine, which uses compressed air to force abrasive media against the surface of the workpiece.

➡️ This type of machine is typically used for smaller pieces of metal or plastic.

Shot peening machines are also available, which use shots (small metal balls) instead of abrasive media to treat the surface of the workpiece. Shot peening is often used to increase the fatigue strength of metals.

Advantages of Shot Blasting

Shot Blasting is a process in which small metal pellets are blasted at high speeds onto the surface of a metal object. This process is used to clean, deburr, or otherwise prepare the metal surface for further treatment.

- Very effective way to remove scale, rust, paint, and other contaminants from metal surfaces.

- Can be used to roughen up a smooth surface to improve adhesion for coating or painting.

- Fast and efficient, and can be done using automated equipment.

- Produces a clean, uniform finish that is free of imperfections.

How to Choose the Right Shot Blasting Machine

There are many different types and sizes of shot blasting machines on the market, so how do you know which one is right for your needs? Here are a few factors to consider when choosing a shot blasting machine:

- The type of material you will be blasting: There are different machines designed for different materials, so it’s important to choose one that is suitable for the type of material you will be working with.

- The size of the job: The size of the machine should be appropriate for the size of the job. If you are only doing small jobs, then a smaller machine would suffice. However, if you plan on doing larger jobs, then you will need a bigger machine.

- Your budget: Obviously, your budget will play a role in your decision. There are both expensive and more affordable options on the market. It’s important to find a machine that fits within your budget while still meeting your needs.

Conclusion…

Shot blasting is an effective way of cleaning and prepping surfaces for painting or additional treatments. This process is fast, efficient, cost-effective and can provide a superior finish compared to other methods.

It also has the advantage of being low risk with minimal environmental impact. Whether you’re looking to restore existing parts or create paint-ready surfaces from scratch, shot blasting offers many advantages that make it well worth considering for your project.

More Details

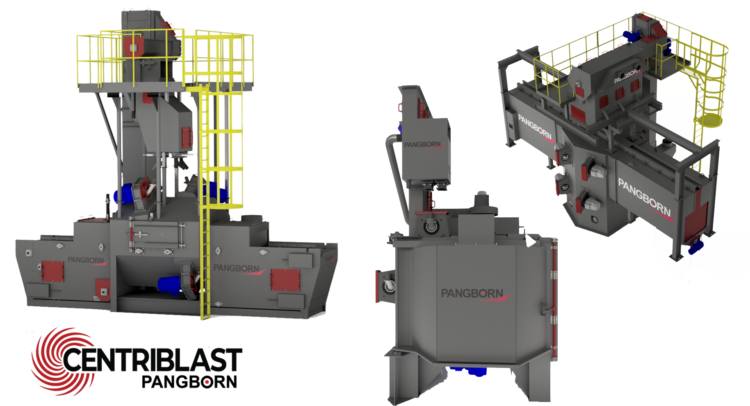

If you’d like more details on shot blasting equipment manufactured and supplied by Centriblast – Pangborn. Get in touch with our specialist team to discuss your options. Call us on 01352 712 412 or email us at – info@pangborn.co.uk.