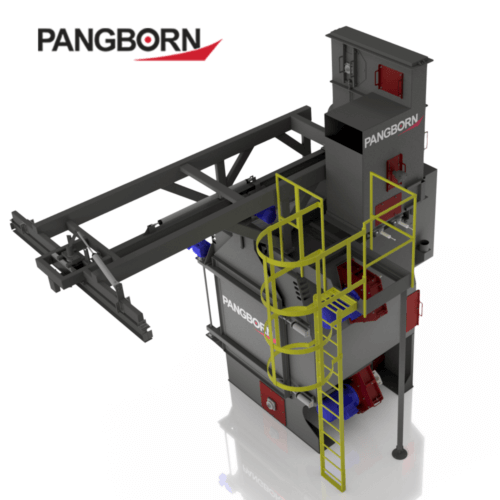

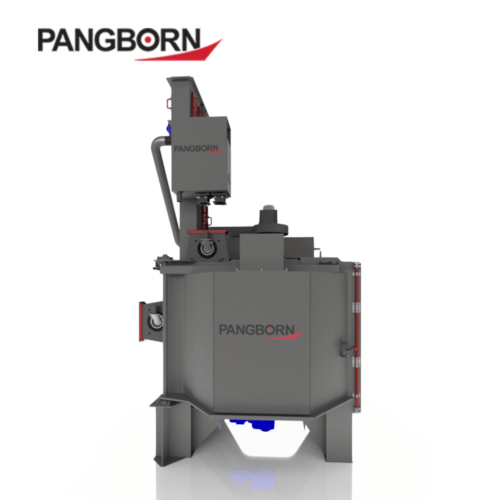

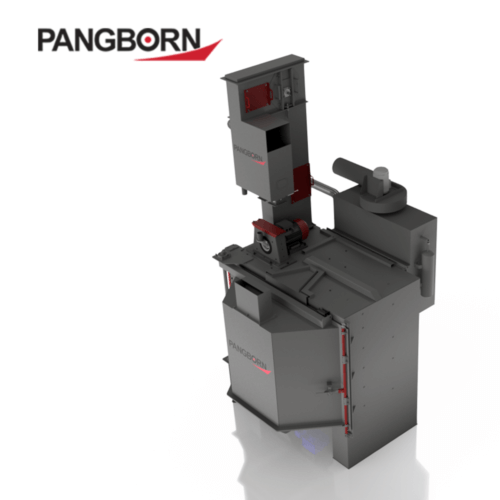

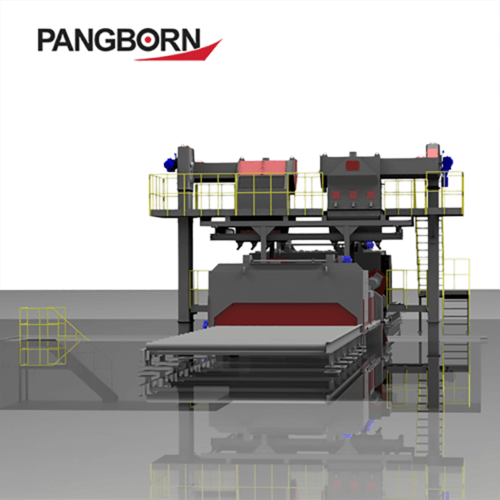

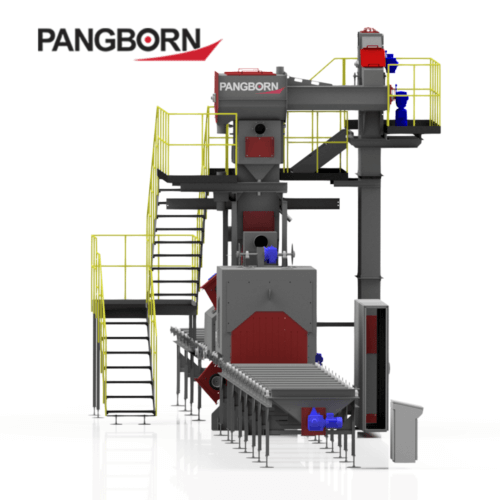

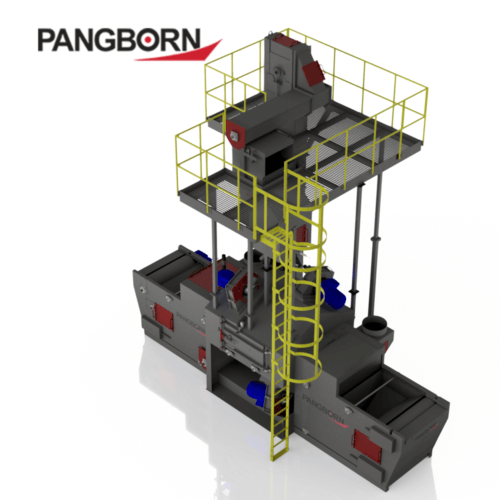

Pangborn Heavy Duty GN Barrel Blast Machines (Metal Belt) tumbling action, provided by the endless rubber or metal internal conveyor, ensures all surfaces of the work piece are cleaned in one loading.

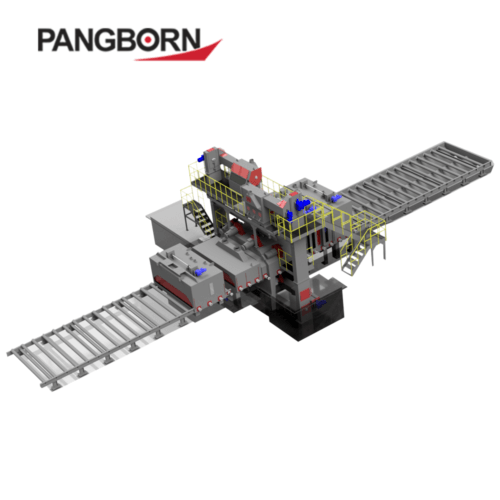

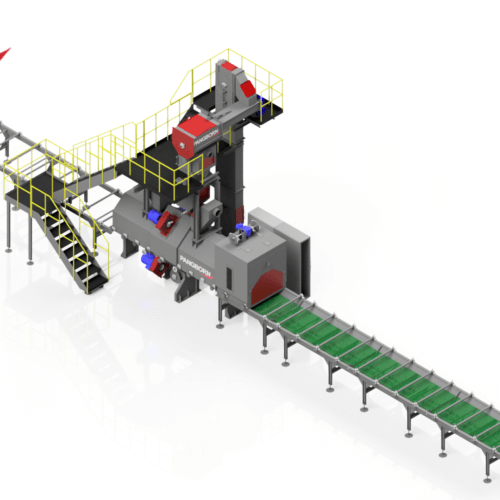

Highly configurable, these machines can be delivered with a rubber or metal conveyor, vibratory conveyor, magnetic separator, hydraulic loader, unloading conveyor, and dust collector.

The loading and unloading process is specifically geared to the work piece and workspace requirements. The optimum adjustment of the blast capacity is specified to the required blasting result. The tumbling action provided by the rubber or metal conveyor ensures that all surfaces of the work piece are cleaned in a single batch.

Pangborn offers a variety of barrel sizes depending on the size of the work pieces being blasted. Most often, larger machines are used for high output cleaning on medium sized castings, forgings, or fabricated work pieces. Barrel Blast Machines allow for a high volume of work pieces to be processed in a small working area.

Finishing Process & Applications

- Ideal for processes including deburring, descaling, decoring, deflashing, and peening

- When throughput requirements dictate batch processing

- Small- to medium-sized castings, fabrications, and heat-treated work pieces

- Shot peening small springs in batch capacities

- Lower value work pieces where part-on-part impingement is not an issue

Reviews

There are no reviews yet.