The machine body is inclined in the flow and transverse direction, and the blast wheels are installed on the two longitudinal directions and cover section sides. The transverse inclination is adjustable depending on the work pieces to be blast cleaned.

The Continuous Belt Conveyor Blast Machine is ideal for symmetric, sensitive work pieces. Our Roller Conveyor Blast Machines are the right solution for heavy plates and structural shapes. Lastly, our Monorail Conveyor Blast Machines are preferred by customers who are blasting heavy work pieces at a high pass through rate.

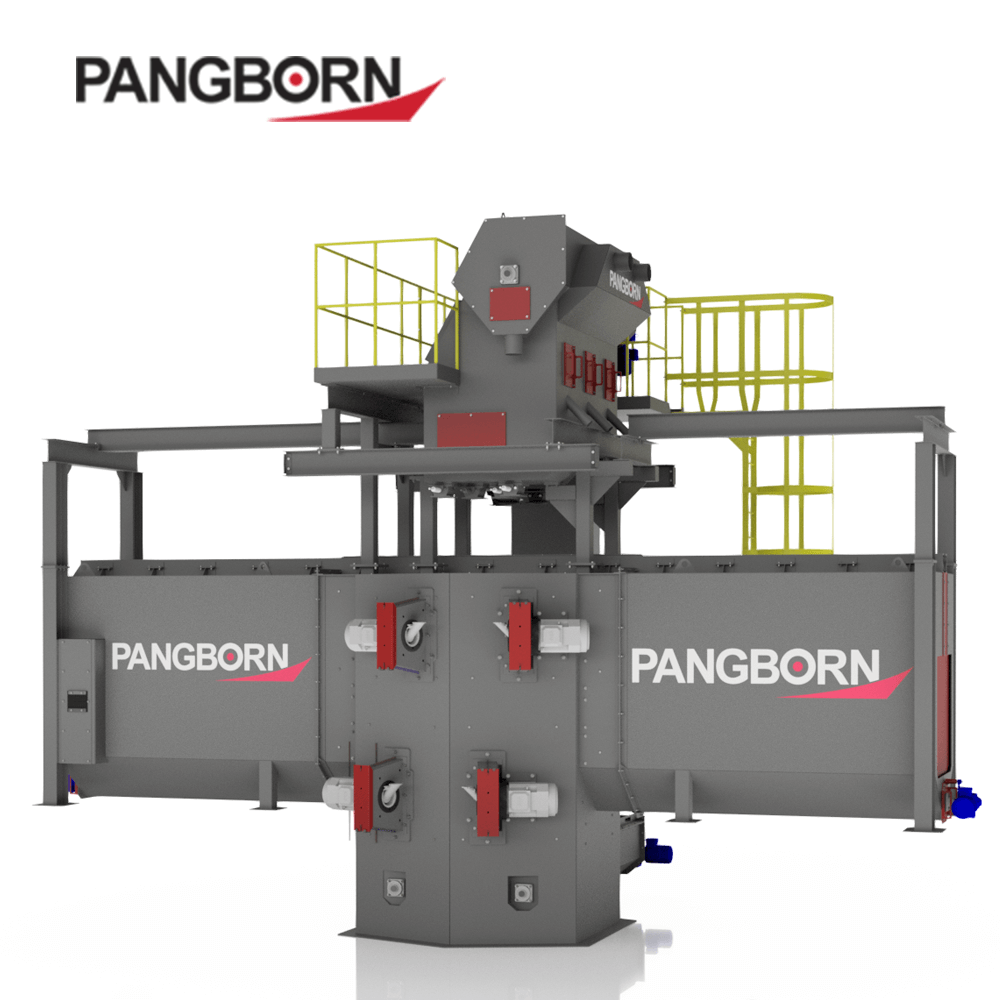

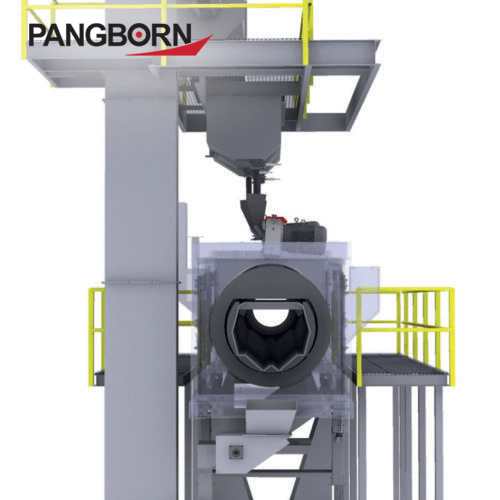

Belt Blast Conveyor

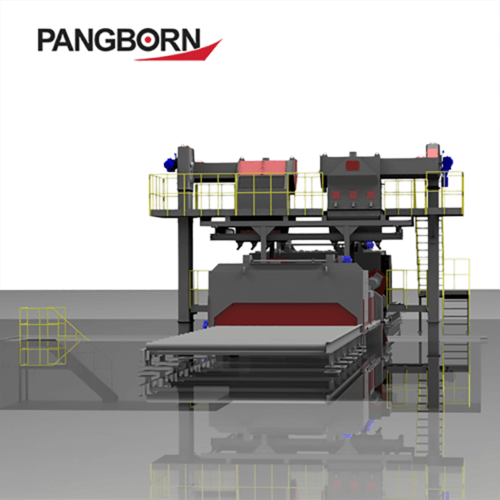

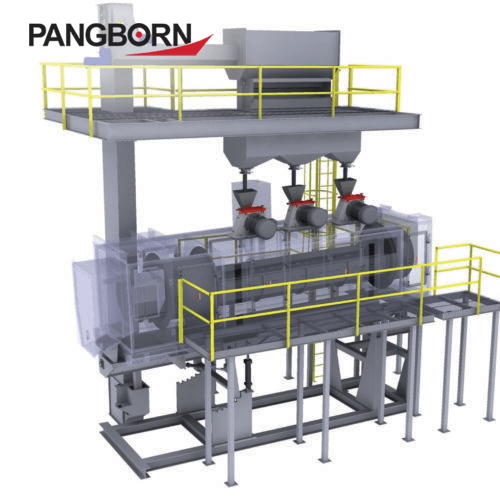

Featuring an endless belt conveyor, the Pangborn Continuous Belt Conveyor Blast Machine is ideal for rotation-symmetric shock and vibration sensitive work pieces (brake drums, brake discs, wheel rims, etc.). Work pieces are blast cleaned in a continuous flow and in a reliable, cost effective manner.

The machine body is inclined in the flow and transverse direction, and the blast wheels are installed on the two longitudinal directions and cover section sides. The transverse inclination is adjustable depending on the work pieces to be blast cleaned.

Finishing Processes and Applications

⦿ Brake drums and discs

⦿ Wheel rims

⦿ Models CBC

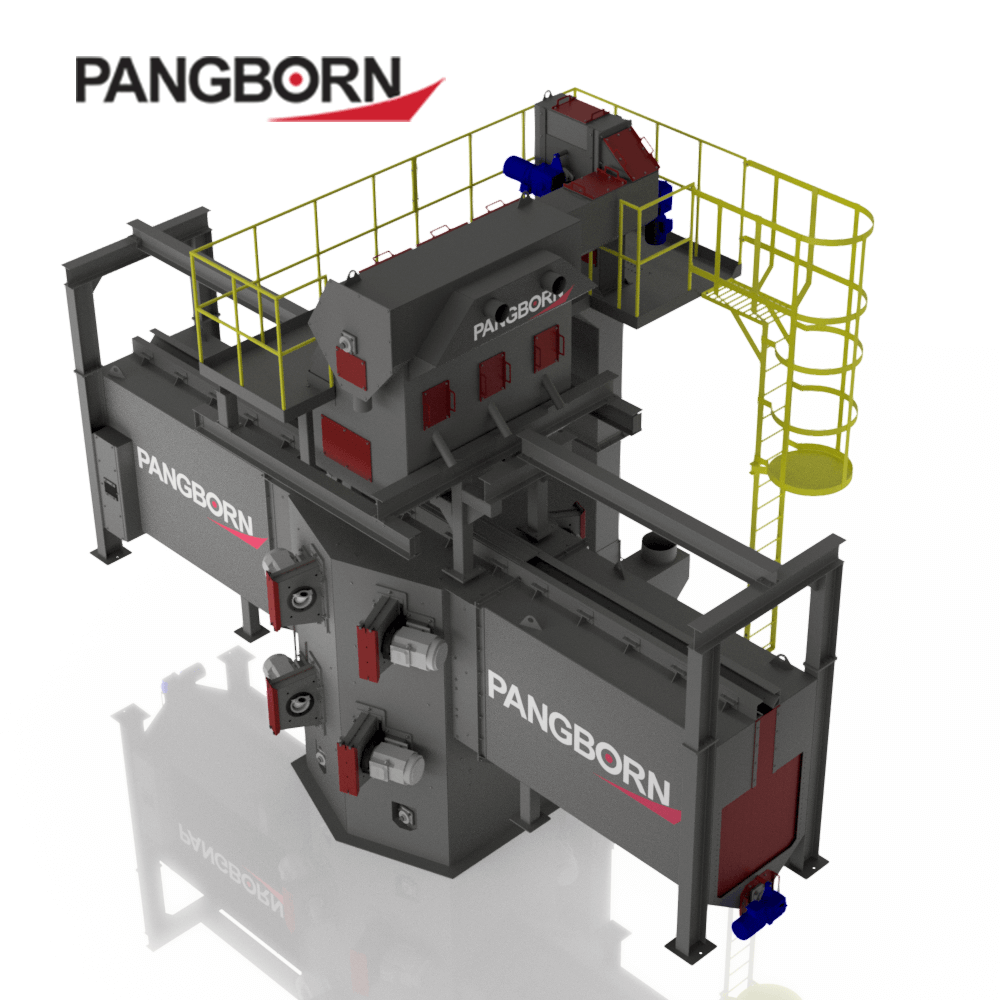

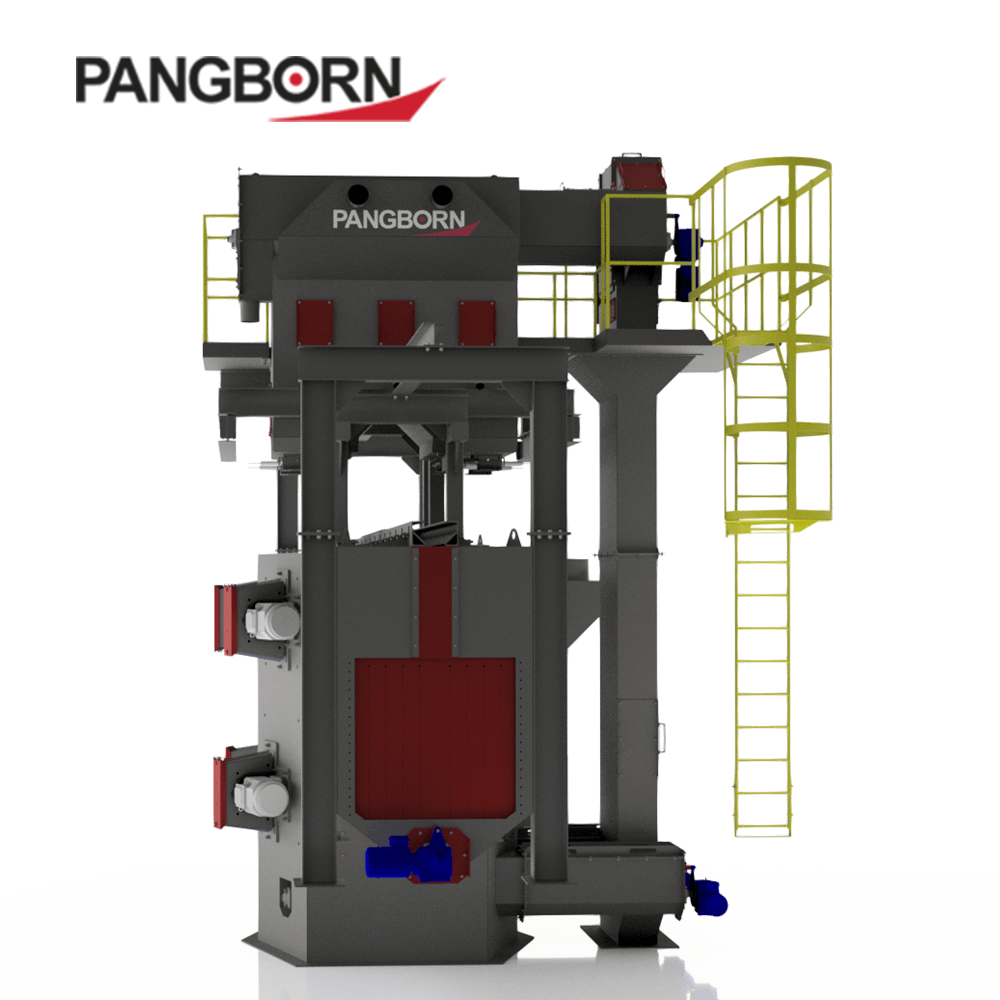

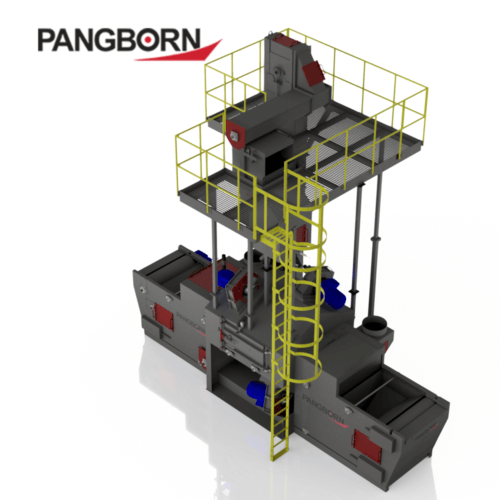

Monorail Conveyor

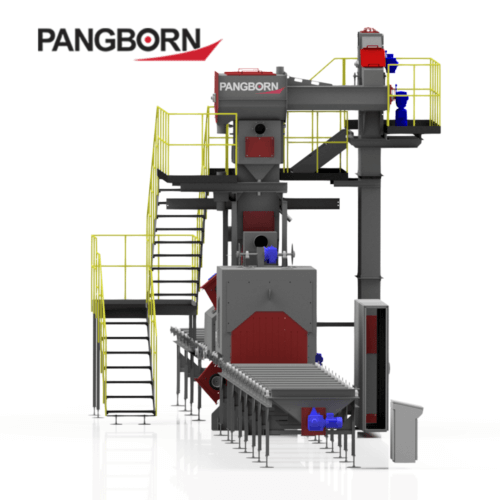

Pangborn’s Monorail Conveyor Blast Machines are usually recommended for use in situations that require blasting heavier work pieces at a high rate. These machines are exceptionally configurable and use as many as 24 blast wheels for outstanding speed without sacrificing coverage. Because of the overhead conveyor system, these machines are perfect for moving heavier work pieces through the blast chamber, and depending on the work and speed required, a monorail, “power & free”, or self-driving trolley may be employed.

Our Monorail Conveyor Blast Machines are all constructed to meet heavy duty applications and use extremely durable special alloy liners for increased longevity. Depending on the customer’s requirements, several solutions are available including those with special and wear resistant hooks.

Finishing Processes and Applications

⦿ High production rates

⦿ Blasting heavier work pieces

⦿ Derusting, roughening, finishing, sweeping, and descaling forgings or hardened steel work pieces

⦿ Desanding and final blast cleaning of castings

⦿ Shot peening

⦿ Deburring of plastic

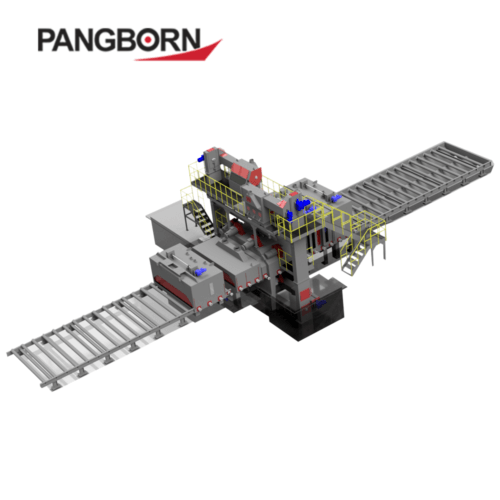

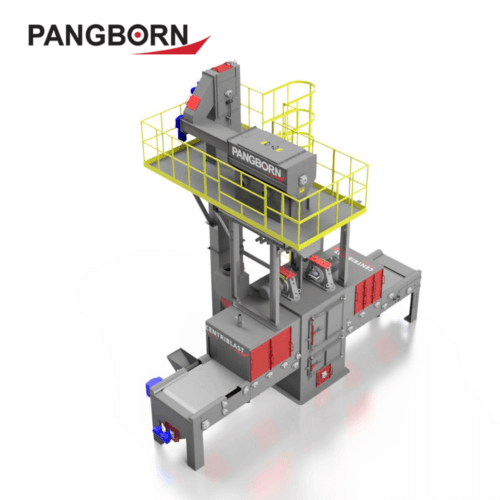

Roller Conveyor

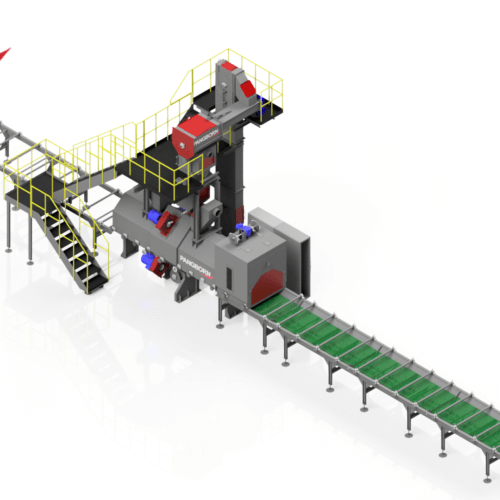

The use of Pangborn’s Roller Conveyor Blast Machine system for descaling is a cost-effective means of reducing today’s high manufacturing expenses while improving the quality of work.

A clean, rust, and scale-free surface is a fundamental requirement for the anti-corrosion treatment of rolled steel products (sheet metal plates, rolled sections, tubes, and simple structural steel work). Because several plate and structural shapes are often extremely heavy and large, a roller conveyor machine is usually the only method used to safely and thoroughly clean these types of work pieces.

Finishing Processes and Applications

⦿ Structural steel

⦿ Mill scale removal

⦿ Profiling

⦿ Paint preparation

Models

⦿ ES-1860, ES-1834, ES-1838, ES-1844, ES-1848, ES-1821, ES-1885

⦿ RC

Reviews

There are no reviews yet.